Product

Functional Additives for Plastic and Rubber

Functional additives play a crucial role in the production of plastic and rubber materials, imparting specific characteristics that improve performance, durability, and versatility. These additives are introduced during manufacturing through methods such as masterbatches, compounds, or direct dosing to provide customized functionalities like flame retardancy, anti-static properties, enhanced mechanical strength, and clarity, among others. By allowing plastics and rubber to comply with strict industry standards and broaden their application possibilities, functional additives greatly enhance the value and utility of the finished products.

Our product range features a diverse array of functional additives tailored to meet various industrial requirements. Key categories include Vulcanization Accelerator Masterbatch, Activator, Blowing Agent, Rubber Plasticizer, Composite Masterbatch Particles, Coupling Agent, Anti-scorching Agent, Adhesive System Additive, Staple Fiber Reinforcement, Uniform Agent, Cross-linking Agent, Metal Oxide, Plasticizing Agent, Tackifying Resin C5/C9 Copolymer Petroleum Resin, and Anti-aging Agent. Each category is specially formulated to provide targeted enhancements, ensuring optimal performance across multiple applications.

Whether your goal is to boost flame resistance, improve processing efficiency, or prolong material lifespan, our functional additives offer dependable solutions for industries such as construction, electrical, automotive, and more. Explore how our additives can enhance the performance and value of your plastic and rubber products.

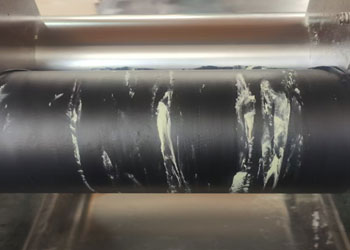

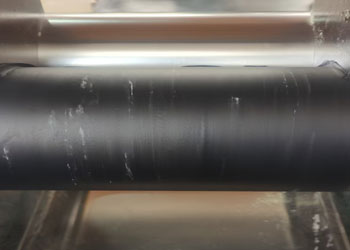

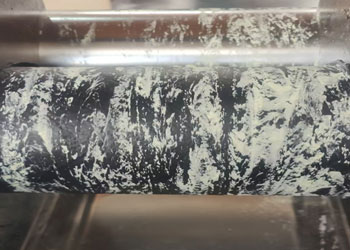

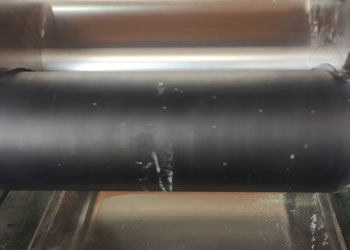

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

cwc@jxbh-masterbatch.com

cwc@jxbh-masterbatch.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.