MTT-80

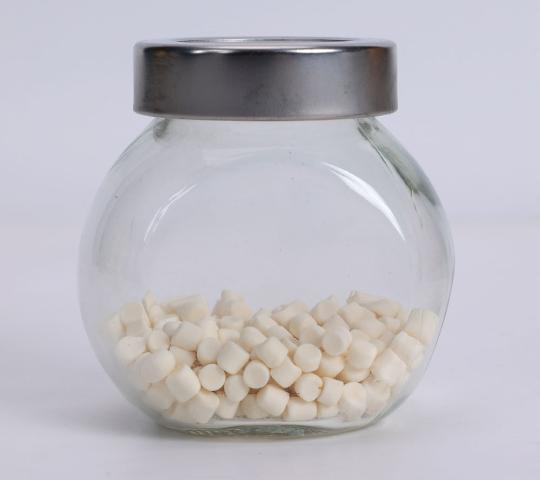

Product Name:MTT(CRV/LG)-80

Composition:80% 3-methylthiazolidine-2-thione, 20% Carrier and dispersing agent

Appearance:White or Grey particles

Density:About 1.10g/cm3

Filtration(μm):500

-

Description

Chemical Rubber Accelerator MTT is a thiazole heterocyclic compound, which contains active sulfur atoms, halogen-containing polymer can produce cross-linking. Particularly suitable for chlorinated butyl rubber, chloroprene rubber, chlorinated polyethylene rubber vulcanization.

-

Function

JXBHgran MTT-80 is a thiazole heterocyclic compound containing active sulfur atoms to crosslink the halogen-containing polymer. Applicable to chlorinated butyl rubber, chloroprene rubber vulcanization crosslinking, in particular, can be used as chloroprene rubber efficient accelerator. Compared with ETU-75 masterbatch, this product retains good physical and aging resistance, improves the scorch performance and operation of the compound safety. Both have a faster curing characteristics.

-

Dosage

Chloroprene rubber: 0.4-1.5 phr with 4.0 phr of magnesium oxide or 5.0 phr of zinc oxide or 20.0 phr of lead oxide. Low rubber content of the compound or add light-colored filler of the rubber: To achieve the best mechanical processing performance, 0.5-1.0 phr and 0.2-1.0 phr sulfur.Continuous vulcanization: 0.8-1.5 phr.

-

Application

It can be used in the inner liner of tire, airbags, cables, tape, rubber shoes, hoses, seals, and different industrial products in the compound. Particularly suitable for neoprene.

-

Packing

25 kg in carton box with polyethylene bag liner.

-

Storage

Cool and dry conditions, the storage period of one year.

-

Chemical Properties

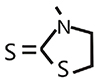

Chemical name: 3-methylthiazolidine-2-thione

Molecule formula: C4H7NS2

Molecule structure:

Molecular weight: 133.32

CAS number: 1908-87-8

Technical indicators: Appearance: Gray-white powder

Initial melting point: ≥ 65℃

Moisture: ≤0.5%

Ash: ≤0.5%

Residue on 150μm sieve: ≤0.1%

Residue on 63μm sieve: ≤0.5%

cwc@jxbh-masterbatch.com

cwc@jxbh-masterbatch.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.