MBTS(DM)-75

Product Name:JXBHgran MBTS(DM)-75

Composition:75% Dibenzothiazole disulfide, 25% Carrier and dispersing agent

Appearance:Light yellow particles

Density:About 1.27g/cm3

Filtration(μm):140

-

Description

Natural rubber and a variety of synthetic rubber with Chemical Rubber Accelerator MBTS(DM) can produce floating and medium-speed vulcanization. There is a significant post-effect, not early curing, safe operation, easy to disperse, no pollution, and vulcanized rubber aging resistance. This product is a G-type neoprene excellent anti-scorch agent. In neoprene, it can also play a plasticizer or delay agent role.

-

Function

JXBHgran MBTS-75 is a versatile quasi-ultrafast accelerator with good processing safety that can be used alone or in combination with other accelerators. With the activated dithiocarbamate accelerator, it can prevent scorch, and also act as a plasticizer or retarder in neoprene.JXBHgran MBTS-75 can improve processing safety when used in combination with the accelerator. Using JXBHgran MBTS-75 good heat aging resistance can be obtained.

-

Dosage

NR: 1.2-2.2 phr with 2.0-3.0 phr of sulfur.

NBR: 1.2-2.2 phr with 0.2-2.0 phr of sulfur.

SBR: 1.2-3.3 phr with 1.0-3.0 phr of sulfur.

-

Application

Generally used for heat-resistant industrial products, cable sheathing, insulation, and hard rubber.

-

Packing

25 kg in a carton box with a polyethylene bag liner.

-

Storage

Cool and dry conditions, the storage period of one year.

-

Chemical Properties

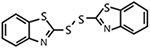

Chemical name: Dibenzothiazole disulfide

Molecule formula: C14H8N2S4

Molecule structure:

Molecular weight: 332.50

CAS number: 120-78-5

Technical indicators: Appearance: Gray-white or light yellow powder

Initial melting point: ≥170℃

Heating loss: ≤0.3%

Ash: ≤0.3%

Residue on 150μm sieve: ≤ 0.1%

Residue on 63μm sieve: ≤ 0.5%

cwc@jxbh-masterbatch.com

cwc@jxbh-masterbatch.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.