Cross-linking Agent

Cross-linking Agent

Cross-linking agents are essential additives that create chemical bonds between polymer chains, transforming raw materials into robust, three-dimensional networks with enhanced mechanical, thermal, and chemical properties. These agents play a pivotal role in vulcanization, thermoset curing, and the production of high-performance elastomers, coatings, and hydrogels. By controlling crosslink density, they optimize material characteristics such as elasticity, resilience, and resistance to deformation.

Our product line includes TAIC, BH-41-IIR, and TAIC-50, each designed to address unique challenges. TAIC, a triazine-based agent, excels in peroxide-cured systems, delivering exceptional crosslink efficiency and heat resistance for automotive and industrial applications. BH-41-IIR is specifically formulated for butyl rubber, accelerating curing rates while improving mechanical strength and durability. TAIC-50, a pre-dispersed masterbatch, ensures uniform crosslinking in rubber and thermoplastic compounds, simplifying processing and enhancing consistency.

Whether you're developing high-temperature seals, resilient coatings, or advanced hydrogels, our cross-linking agents provide the precision and reliability needed to achieve superior material performance.

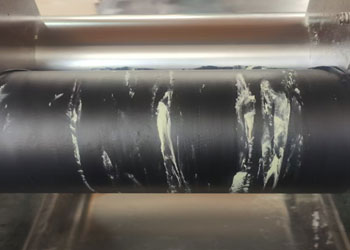

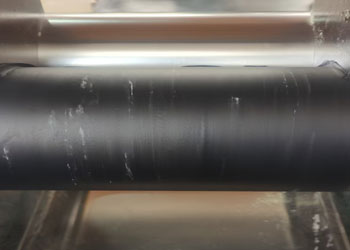

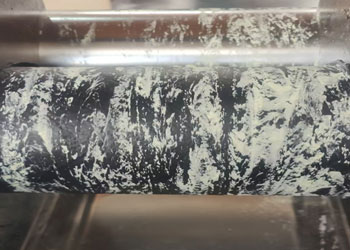

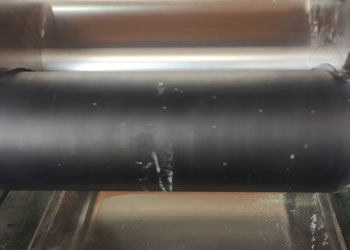

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

cwc@jxbh-masterbatch.com

cwc@jxbh-masterbatch.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.