ZDMC(PZ)-80

Product Name:ZDMC(PZ)-80

Composition:75% of Zinc dimethyl dithiocarbamate, 25% of Carrier and dispersing agent

Appearance:White particles

Density:About 1.42g/cm3

Filtration(μm):120

-

Description

This ZDMC for Rubber Curing is a super accelerators for NR and synthetic rubbers and latex. Especially suitable for IIR and NBR with excellent aging resistance for compression deformation, also suitable for EPDM. The vulcanization temperature is 100°C, and the activity is stronger than TMTD.This product has an activating effect on thiazoles and sulfenamides accelerators and can be used as a second accelerator. When used in combination with accelerator DM, scorch resistance increases as the amount of DM increases. Because it is odorless, non-polluting and does not change color, it is suitable for rubber products such as tape, food and medicine.

-

Function

JXBHgran ZDMC-75 can cause rapid vulcanization of natural rubber and synthetic rubber,such as SBR,NBR,EPDM. And the addition of thiuram and thiazole accelerators can delay the early vulcanization, improve the safety of the operation. JXBHgran ZDMC-75 has longer scorch time and complete curing rate than ZDBC-75.

-

Dosage

NR: 0.3-0.8 phr Second accelerator, 0.05-0.3 phr.

SBR / NBR:0.8-1.2 phr Second accelerator, 0.05-0.3 phr.

-

Application

Mainly used for light-colored products, transparent rubber utensils, wire and cable, etc.

-

Packing

25 kg in carton box with polyethylene bag liner.

-

Storage

A cool and dry condition, the storage period of one year.

-

Chemical Properties

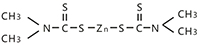

Chemical name: Zinc dimethyldithiocarbamate

Molecule formula: C6H12N2S4Zn

Molecule structure:

Molecular weight: 305.81

CAS number: 137-30-4

Technical indicators: Appearance: White powder

Initial melting point: ≥240℃

Residue on 150μm sieve: ≤0.1%

Residue on 63μm sieve: ≤0.5%

Heating loss: ≤0.4%

Zinc: 20%-23%

cwc@jxbh-masterbatch.com

cwc@jxbh-masterbatch.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.