TMTD(TT)-80

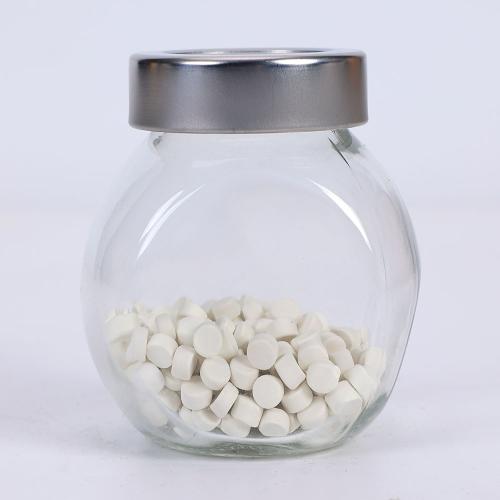

Product Name:JXBHgran TMTD(TT)-80

Composition:80% Tetramethyl thiuram disulfide, 20% Carriers and dispersing aids

Appearance:Gray-white particles

Density:About 1.15g/cm3

Filtration(μm):140

-

Description

TMTD(TT) Masterbatch can be used as a super vulcanization accelerator in the rubber industry, and it can be used not only with thiazole accelerators but also with other accelerators as a synergist. As it can be slowly decomposed to free sulfur above 100 ℃, it can be used as a curing agent. The product is excellent in aging resistance and heat resistance. Applicable to natural rubber, and synthetic rubber. It is mainly used in the manufacture of tires, inner tubes, rubber shoes, cables, and other industrial products. It can not only be used as a fungicide and pesticide in agriculture but also as lubricant additives.

-

Function

JXBHgran TMTD-80 is an accelerator for fast vulcanization of natural and synthetic rubbers, and also a vulcanizing agent in low-sulfur or non-sulfur curing systems.

-

Dosage

0.2-2.0 phr.

-

Application

Mainly used in the manufacture of tires, rubber shoes, cables, and other industrial products.

-

Packing

25 kg in a carton box with a polyethylene bag liner.

-

Storage

Cool and dry conditions, the storage period of one year.

-

Chemical Properties

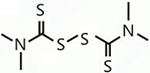

Chemical name: Tetramethyl thiuram monosulfide

Molecule formula: C6H12N2S4

Molecule structure:

Molecular weight: 240.41

CAS number: 137-26-8

Technical indicators: Appearance: white to gray-white powder

Initial melting point: ≥142℃

Heating loss: ≤0.3%

Ash: ≤0.3%

Residue on 150μm sieve: ≤ 0.1%

Residue on 63μm sieve: ≤ 0.5%

cwc@jxbh-masterbatch.com

cwc@jxbh-masterbatch.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.