CTP(PVI)-80

Product Name:JXBHgran CTP(PVI)-80

Composition:80% N-cyclohexylthiophthalimide, 20%Carrier and dispersing agent

Appearance:Beige particles

Density:About 1.13g/cm3

Filtration(μm):200

-

Description

This Rubber Masterbatch CTP-80 can prevent early curing of the rubber compound during processing and improve the processing safety, while it has almost no effect on the vulcanization rate and vulcanizate properties. For it can effectively prevent scorching, the high temperature and high speed operation of the calender and the extruder can be made possible, and the powerful vulcanization activator can be effectively used to increase the production capacity of vulcanization machine. This product has a rejuvenating effect for rubber which has been subjected to high temperatures due to seasons, handling, and improper operation, or a compound that can not be further processed with the risk of scorching.

-

Function

JXBHgran CTP-80 is a kind of antiscorching agent. It can delay NR and SR starting vulcanization time without affecting the overall curing time. It can also improve the processing safety without affecting the performance of vulcanized rubber with sulfonamide and thiazole accelerator used together. JXBHgran CTP-80 can significantly improve the storage stability and high temperature of unvulcanized rubber processing safety performance, and fully improve the production capacity of equipment. The use of the product will not cause contact contamination.

-

Dosage

0.2-2.0 phr.

-

Application

The product is mainly used for natural rubber and synthetic rubber which use sulfonamides or thiazoles as the main accelerator.

-

Packing

25 kg in carton box with polyethylene bag liner.

-

Storage

Cool and dry condition, the storage period is one year.

-

Chemical Properties

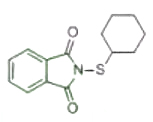

Chemical name: N-cyclohexylthiophthalimide

Molecule formula: C14H15O2SN

Molecule structure:

Molecular weight: 261.34

CAS number: 17796-82-6

Technical indicators: Appearance:White powder or crystalline powder

Initial Melting Point:≥90℃

Heating loss:≤0.3%

Ash:≤0.1%

cwc@jxbh-masterbatch.com

cwc@jxbh-masterbatch.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.