CBS(CZ)-80

Product Name:JXBHgran CBS(CZ)-80

Composition:80% N-cyclohexyl-2-benzo thiazole sulfonamide, 20%carrier and dispersing aids

Appearance:Gray-white particles

Density:About 1.10g/cm3

Filtration(μm):140

-

Description

CBS(CZ) Vulcanization Accelerator can be used in natural rubber and synthetic rubber. Even it is applicable to almost all rubber products including tires, rubber hose, industrial products, household items, and sponge products, etc.

-

Function

JXBHgran CBS-80 is a kind of highly active after effect accelerator,with excellent scorch resistance performance, processing security,and short vulcanization time.When curing temperature above 138 ℃, it will present a strong role in accelerating. Generally, it is used together with TMTD, DPG or other alkaline accelerators as the second accelerator. Alkaline accelerator, such as Thiurams and Dithiocarbamate salts, can enhance its activity.

-

Dosage

NR:0.5-1.0 phr and 2.5-3.5 phr sulfur use simultaneously.

0.5 phr and 1.5-3.0 phr sulfur and 0.3 phr Thiurams use simultaneously.

SBR:1.0-1.4 phr and1.5-2.5 phr sulfu rand0-0.2 phr Thiurams use simultaneously.

-

Application

Commonly used to tread, hose, conveyor belt, soles, etc.

-

Packing

25 kg in carton box with polyethylene bag liner

-

Storage

Cool and dry condition, the storage period is one year.

-

Chemical Properties

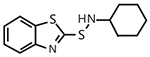

Chemical name: N-cyclohexyl-2-benzo thiazole sulfenamide

Molecule formula: C13H16N2S2

Molecule structure:

Molecular weight: 264.41

CAS number: 95-33-0

Technical indicators: Appearance: Gray-white powder

Initial Melting Point:≥98℃

Heating loss:≤0.4%

Ash:≤0.3%

Residue on 150μm sieve:≤0.1%

Residue on 63μm sieve: ≤0.5%

cwc@jxbh-masterbatch.com

cwc@jxbh-masterbatch.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.