Staple Fiber Reinforcement

Chopped Fiber Reinforcement

Chopped fiber reinforcement enhances the mechanical properties of injection and compression molding compounds across matrices such as thermoset/thermoplastic resins, rubber, and cement. Available in tailored lengths (3–24 mm), these fibers improve strength, stiffness, and dimensional stability in high-performance applications like automotive brakes/clutches and electrical housing components.

Our APM40 chopped fiber is engineered for superior reinforcement efficiency. With optimized fiber length and high bulk density, APM40 ensures consistent dispersion during compounding, minimizing processing challenges while maximizing load-bearing capacity. Compatible with engineering thermoplastics (e.g., PC, Nylon) and high-temperature resins (e.g., PEEK, PEI), it delivers exceptional strength-to-weight and stiffness-to-weight ratios.

APM40 excels in demanding environments, offering seamless integration into pellets, flakes, or custom forms to suit diverse manufacturing needs. Elevate your composites with APM40’s balanced flow characteristics, enhanced processability, and reliable performance in automotive, aerospace, and industrial applications.

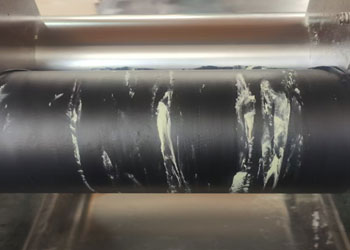

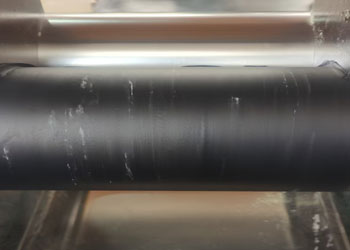

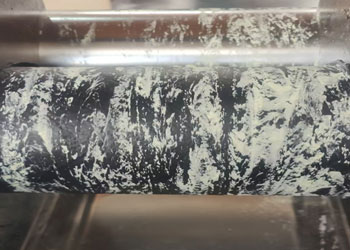

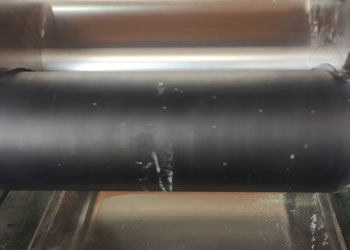

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

cwc@jxbh-masterbatch.com

cwc@jxbh-masterbatch.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.